Managing industrial refrigeration equipment across multiple sites presents complex challenges. Our client, a leading provider in this industry, sought an enterprise-level solution for enhanced visibility into system health and performance. With Canopy, they gained the power of remote monitoring and automated equipment management. Discover how Canopy revolutionized their operations by generating proactive alerts, conducting remote recovery, and ensuring product preservation and operator safety.

Managing industrial refrigeration equipment across multiple sites presents complex challenges. Our client, a leading provider in this industry, sought an enterprise-level solution for enhanced visibility into system health and performance. With Canopy, they gained the power of remote monitoring and automated equipment management. Discover how Canopy revolutionized their operations by generating proactive alerts, conducting remote recovery, and ensuring product preservation and operator safety.

1. Lack of centralized monitoring and support for legacy refrigeration equipment, resulting in performance delays and high support costs.

2. Reactive support due to limited alert visibility and manual intervention requirements for issue resolution.

3. Difficulty in identifying root causes, often arising from a combination of hardware, software, or network issues.

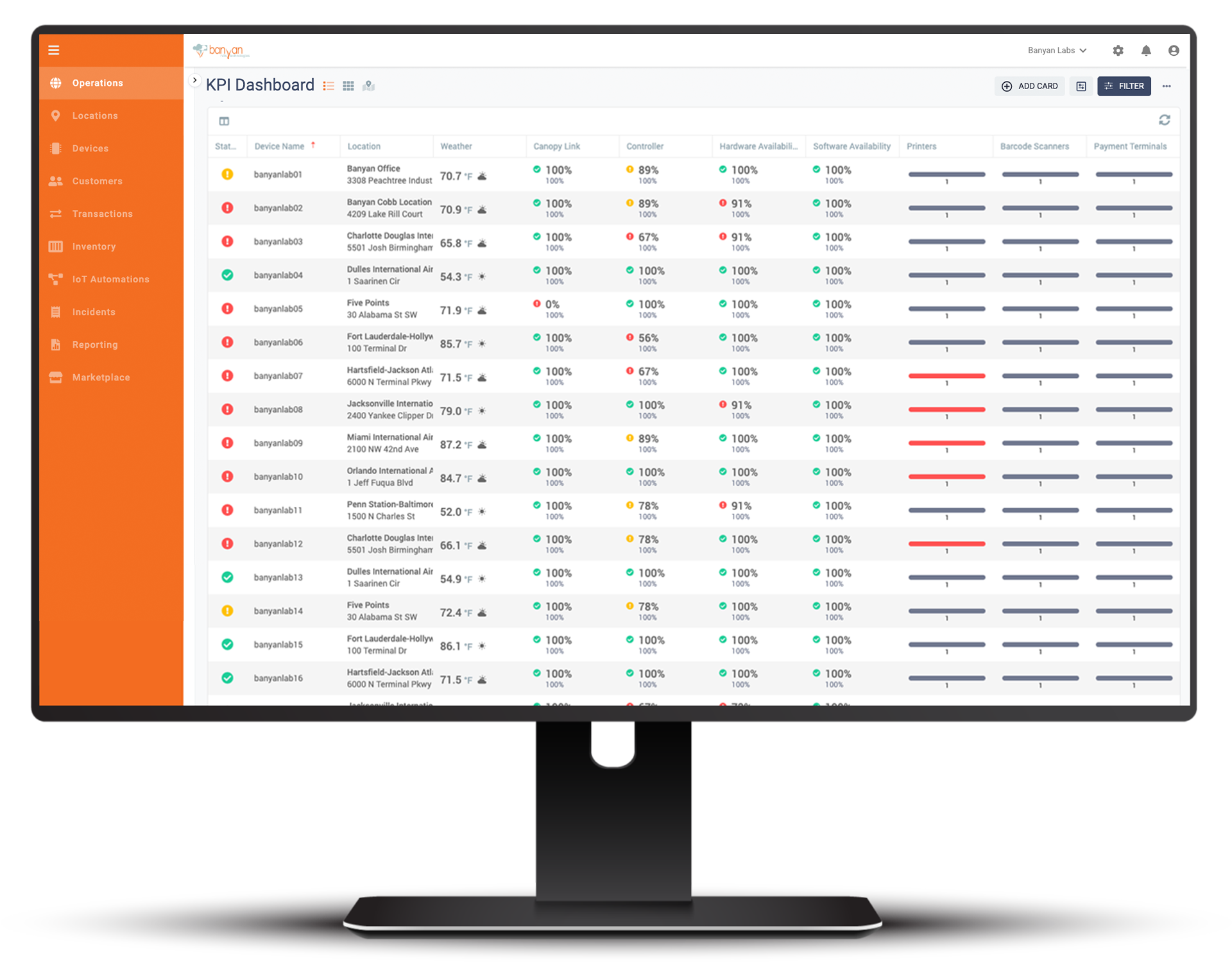

Canopy was seamlessly installed on the refrigeration control system hardware (a Windows controller), allowing the device health status to report into Canopy. Additionally, Canopy integrated with the client's custom-built refrigeration control software application, providing comprehensive visibility into real-time system performance. With Canopy's hardware monitoring and software integration, our client gained full visibility and control over all its critical system elements.

• Thousands of automations and remote actions have saved hundreds of on-site man-hours.

• Prevented system downtime, mitigating food spoilage and liability concerns.

• Account managers now facilitate monthly performance updates with key clients, driven by Canopy's historical performance reports and tailored data analysis to their facilities.