Remote Monitoring and Management's (RMM) Impact on Field Services

RMM technology has revolutionized the Field Services industry by enabling providers to be more proactive and efficient in serving diverse markets.

Remote Monitoring and Management's (RMM) Impact on Field Services

Driving through any major metropolitan area, you will see maintenance vehicles on the road on their way to a service visit. Some may be visiting a home for HVAC unit repair, while others might be headed to a retailer to support broken point-of-sale machines. Despite the differences in technology supported, Field Service Providers have uniformly embraced new digital strategies centered around increasing speed and onsite efficiencies.

Many service companies offered Service Level Agreements (SLA) with their clients to get onsite within 4 hours of a call. Often the Field Service Rep would get there in time, but with no prior insight on the issue or if they needed a particular replacement part to fix the issue. Field Service Providers began to realize they needed digital ways to get smarter about the device before getting onsite and better ways to recognize potential issues before getting a call. As a result, Remote Monitoring and Management (RMM) tools started getting adopted by Field Service Providers.

By leveraging real-time monitoring that allowed them to see system health, they were no longer just reacting to calls from angry customers from the field. Being able to continuously monitor devices assured them that any issues or anomalies would be detected immediately and most importantly before their customer called. Remote Monitoring and Management software has enabled Field Service Providers to become proactive in issue identification, making them more efficient in their onsite visits and with resource allocation.

How Remote Monitoring and Management (RMM) Technology has Changed Field Services

Many Field Service Providers have now transformed their business from a reactive model that simply waits around for phone calls and tickets to now being proactive and preventative towards their customers. This digital transformation has already changed the face of the Field Service industry, but the best providers continue to double down on their technology and ask for new ways to use these tools.

Today, many Field Service Providers leverage their RMMs to automate repetitive tasks and known workflows. Additionally, by analyzing data collected in their RMM, they can leverage advanced analytics to identify patterns and correlations that indicate potential issues or failure risks. These predictive maintenance analytics can be used to spot when maintenance is likely to be required, allowing organizations to proactively minimize downtime and optimize resource utilization.

Remote Monitoring and Management solutions enable Field Service Providers to drive better workforce efficiency and take more ownership of the support value chain. Many Field Service Providers are now offering services such as asset management and remote support services, which create new revenue streams.

Looking into the Future of Field Services, What Comes Next?

So, the question for Field Service Providers is what’s next? How can they continue to grow their business and maintain efficiencies?

Early data indicates that Field Service Providers are starting to expand into new verticals, driven by the growth of smart technologies and connected products that need field service support. These connected products, spanning various industries, have shifted Field Service Providers from their traditional focuses to new markets. For instance, a service provider previously servicing ATMs in the financial sector may now target self-checkout systems in the retail and grocery industries. Similarly, those once dedicated to retail security equipment might now concentrate on access control systems within the multi-tenant housing market. Consequently, a service technician leaving home for the day will need to be prepared to support vastly different technology solutions as issues come up.

The Challenge: Historically, service providers have focused narrowly on a specific vertical or product and had a tailored RMM tool for that single product or vertical. As providers enter new markets, questions arise: do they need to invest in separate tooling for each type of device they support? For instance, if they support products from eight OEMs, do they need eight different RMM tools? The challenge extends to building internal expertise when the team must navigate between different programs. Moreover, how is growth managed when adding another OEM to their portfolio? Would this necessitate learning a ninth tool? This scenario underscores their dilemma: despite evolving their service offerings, they continue to rely on the same tools as before. As they have transformed their business models, there is a pressing need for a transformative tool that caters to their evolving requirements.

The Answer: The solution lies in flexible Remote Monitoring and Management tool that can horizontally integrated to support multiple OEMs, industries, and product types. This concept may seem ambitious, given the diversity across industries. However, the key is in designing an RMM platform that leverages the service team's existing expertise. By creating a self-serving tool, the customer service team, armed with best practices, can configure the system to support a wide range of OEMs, whether eight or nine, streamlining operations across various sectors.

How Does a Horizontal RMM Platform Work for Field Service Providers?

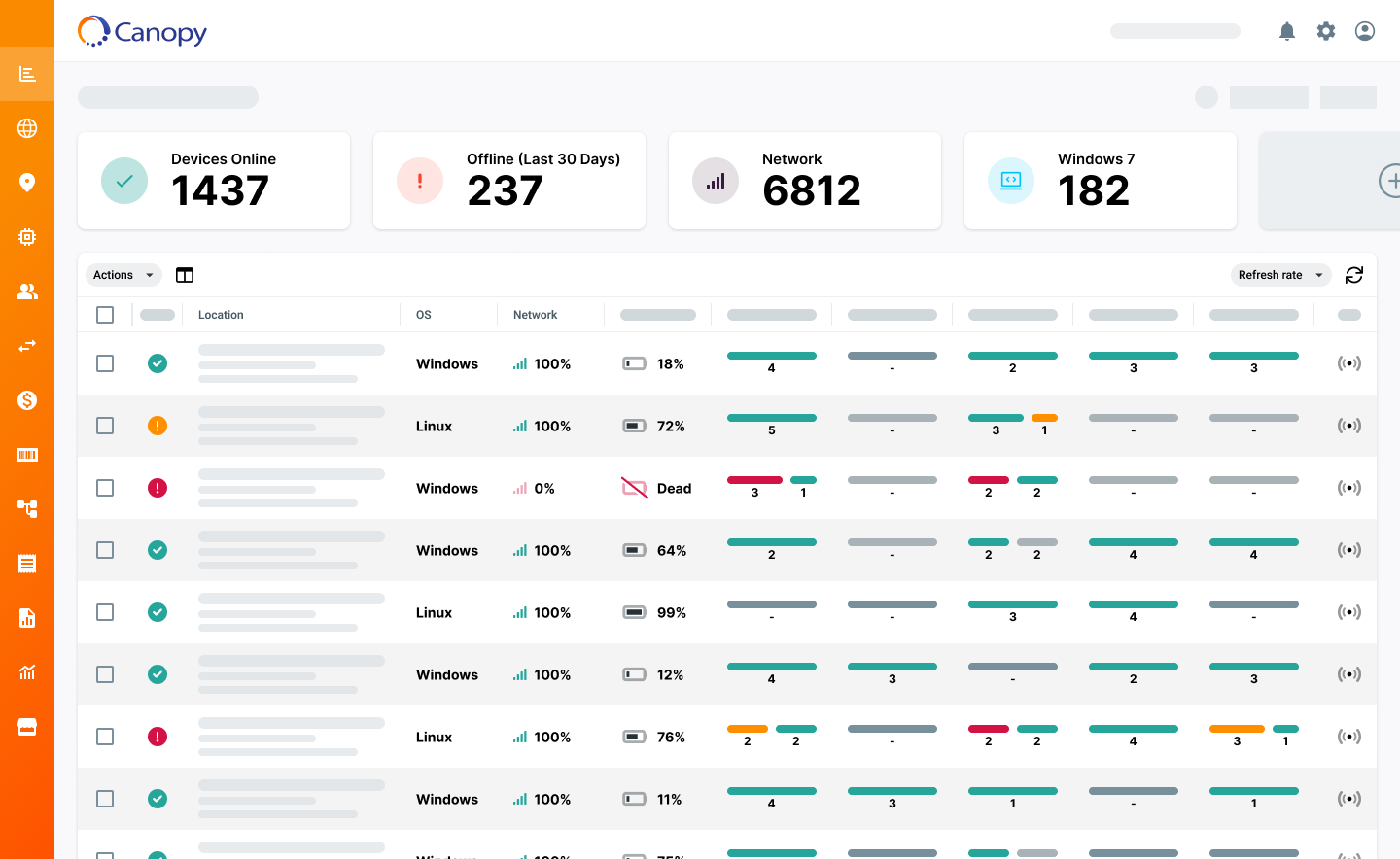

Let's revisit the fundamental problem Field Service Providers solve for their customers: reducing device downtime. Whether it’s a vending machine, HVAC system, or security camera, they need to collect real-time data on crucial device attributes and report them inside their RMM solution to make optimal support decisions. With this data, the RMM tool can dynamically display live health status, enabling proactive and remote management. This way a support center can manage different OEMs simultaneously. They can develop automation workflows to resolve issues remotely and for necessary visits, the RMM provides the technician with all the necessary information for success on-site.

Field Service Providers who have invested in the right RMM no longer pitch 4-hour SLAs; now, they can have eyes on a machine in seconds. Horizontal RMM technology enables Field Service Providers to expand their customer base without proportionally increasing support staff and helps them recognize trends in site visit frequencies, durations, and reasons, bringing critical insights to the forefront. These insights inform customers about their technology choices, facilitating better deployment decisions.

Field Service Providers can also reduce service tickets and alerts through automation. They shorten the open ticket duration by remotely controlling connected technology, enhancing overall deployed availability with constant, real-time data views from their devices. When technicians arrive on-site, their systems precisely indicate the required actions. This means the service provider’s customers experience fewer tickets and alerts, shorter issue resolution times, increased overall fleet availability, and no wasted technician time on-site. This epitomizes a Field Service Provider utilizing a dynamic, cutting-edge RMM platform to reduce customer downtime.

Rethinking your RMM Tool for Field Services? We May be Able to Help.

If you are interested in learning if our horizontal RMM software platform, Canopy, may be able to help your Field Service team uplevel its remote management capabilities, we’d love to meet you.

Today we work with several of the global leading Field Service providers to unlock new markets and operational efficiencies. We’d love to help you with a free evaluation of your remote management and support structure to see if Canopy may be the right RMM solution for your business. Reach out via our website to get in touch with one of our Field Service Provider experts.